| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : HuiYi-PPGL

Model Number : CGLCC,G550

Certification : ASTM, JIS, GB/T

Place of Origin : China

MOQ : 25MT

Price : Negotiation

Payment Terms : T/T,L/C,D/P

Supply Ability : 5000MT/Month

Delivery Time : 15-30 Days

Packaging Details : Exporting Packing with 3layers including the waterproof plastic film,Waterproof paper - plastic film-metal wrap.

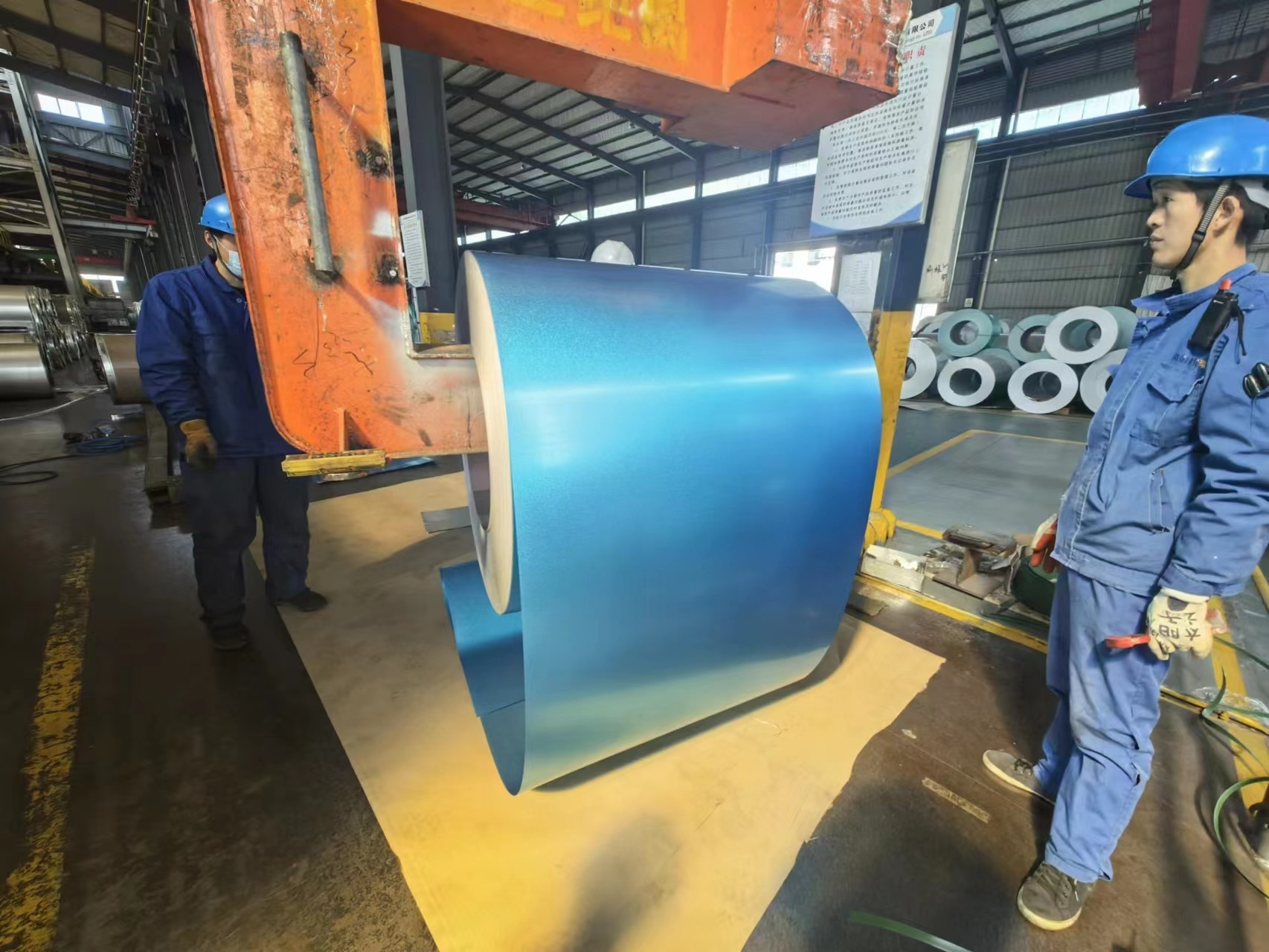

Product Name : PPGL Steel Coil

Material : Galvalume Steel Coil

Size : (0.2-1.5)mm × (600-1250)mm

Color : RAL+Architectural Shades

Coating Type : PE,AKZO,SMP,HDP

Zinc Coating : AZ80-AZ120

Coating Thickness : 15-25μm

Base Material : Galvalume Steel Coils

Salt Spray Resistance : 1,000hrs (ASTM B117)

Wind Uplift Rating : Class F (110mph+)

Engineered for critical building protection, our 120g/m² coated anti-corrosion prepainted galvalume steel coil delivers unmatched defense against harsh environments. Featuring a triple-layer shield - 55% Al-Zn alloy substrate (AZ80-AZ120), heavy 120g/m² polymer coating (PE/SMP/HDP), and anti-fingerprint surface - it outperforms standard building coils with 2X longer service life in coastal/industrial zones. Certified for structural applications up to 200m heights.

| Parameter | Specification |

|---|---|

| Coating Weight | 120g/m² (min) |

| Zinc Coating | AZ80-AZ120 |

| Thickness | 0.2-1.5mm (±0.03mm) |

| Tensile Strength | 320-550 N/mm² |

| Salt Spray Test | 1,000hrs (ASTM B117) |

| Wind Uplift | Class F (ASTM D3161) |

| Thermal Shock | 50 cycles (ISO 6270) |

Industrial Roofing Systems:

Corrosion-resistant standing seam roofs for factories/warehouses

Commercial Curtain Walls:

High-rise cladding with 30-year color warranty

Structural Framing:

Load-bearing columns & beams in corrosive environments

Parking Garage Systems:

Impact-resistant panels with anti-skid surfaces

HVAC Ducting:

Mold-resistant interior linings for hospitals/labs

Coatings: PE (economical), SMP (15yr warranty), HDP (25yr warranty)

Colors: 200+ RAL/Pantone architectural shades + metallic finishes

Surface Textures:

Anti-fingerprint (standard), Stucco, Woodgrain, Embossed

Edge Processing:

Mill edge (coiled), Trimmed edge (sheet cutting)

Special Treatments:

Back-painting for thermal insulation

Military-Grade Protection:

Climate Solutions:

Desiccant bags (tropical regions)

Anti-condensation film (-30°C environments)

Quality Control:

100% coil surface scanning before wrapping

GPS-tracked containers with humidity sensors

Q: Why is 120g coating essential for coastal buildings?

A: Salt spray resistance exceeds 1,000hrs - critical for structures within 5km of coastlines.

Q: Can it be used for seismic zones?

A: Yes, 320-550 N/mm² yield strength complies with IBC 2018 seismic design Category D.

Q: Lead time for custom woodgrain finishes?

A: 22MT minimum in 21 days - sample approval within 72hrs.

Q: Packaging warranty for tropical shipments?

A: 18-month anti-corrosion guarantee with VCI + desiccant combo.

Q: Installation requirements for high-wind areas?

A: Use ASTM C1513-compliant fasteners every 300mm for Class F wind resistance.

Q: How does it compare to standard 80g coating?

A: 50% thicker coating reduces maintenance costs by 40% over 20-year lifecycle.

|

|

120g+ Coating Anti-corrosion Prepainted Galvalume Steel Coil For Building Images |